In terms of cutting-edge technologies, number of items Look at to the sheer precision and efficiency of the laser cutting machine. Envision slicing by way of components with a beam of sunshine so strong it might Minimize via metal as very easily for a knife by means of butter. That’s the magic of a laser cutter. Whether you’re in the market for industrial laser cutting or merely inquisitive about how it really works, understanding this technological know-how can be each interesting and practical.

Laser reducing technologies has revolutionized the manufacturing and layout industries. By focusing a substantial-driven laser beam on a cloth, these devices may make intricate cuts with incredible precision. It’s like getting a Tremendous-experienced artisan who never makes a miscalculation. This precision is important for industries wherever element issues—Feel aerospace, automotive, or electronics. Each and every of those fields relies on laser slicing products to create sections that healthy correctly and performance flawlessly.

Some Known Details About Cnc Laser Cutting

Among the list of standout attributes of laser slicing is its power to manage a variety of elements without difficulty. From metals to plastics, and even fabrics, a CNC laser reducing process can system Virtually nearly anything you toss at it. This versatility makes it an indispensable tool in several sectors. Have you ever ever wondered how your favorite devices or cars are created? Chances are high, they contain some form of laser chopping!

Among the list of standout attributes of laser slicing is its power to manage a variety of elements without difficulty. From metals to plastics, and even fabrics, a CNC laser reducing process can system Virtually nearly anything you toss at it. This versatility makes it an indispensable tool in several sectors. Have you ever ever wondered how your favorite devices or cars are created? Chances are high, they contain some form of laser chopping!Industrial laser cutting goes over and above just precision—it also enhances efficiency. Conventional slicing approaches is usually gradual and wasteful, but a laser cutter is designed for speed and minimum materials wastage. This is particularly helpful for big-scale production the place every next and each scrap of fabric counts. Consider a manufacturing unit wherever the output line is optimized to run seamlessly thanks to the fast cuts of a laser cutter.

The 7-Second Trick For Cnc Laser Cutting

Precision laser chopping is just not almost making accurate cuts; it’s also about obtaining a significant volume of finish. The thoroughly clean edges left guiding by laser slicing necessarily mean there’s much less require For extra processing or finishing. This will preserve equally time and cash in output. Any time you see an item with beautifully Slash edges, you can guess that a laser chopping equipment was in all probability involved with its development.

Precision laser chopping is just not almost making accurate cuts; it’s also about obtaining a significant volume of finish. The thoroughly clean edges left guiding by laser slicing necessarily mean there’s much less require For extra processing or finishing. This will preserve equally time and cash in output. Any time you see an item with beautifully Slash edges, you can guess that a laser chopping equipment was in all probability involved with its development.Laser reducing companies offer you a good way for companies to access this superior-tech system without having to take a position in their own personal devices. Numerous companies specialise in giving laser reducing solutions, allowing Many others to get pleasure from this technological innovation on a for every-task basis. Whether You'll need a handful of custom items or A large number of equivalent areas, these solutions can offer the exact cuts you would like.

In case you’re considering buying laser cutting machines, it’s crucial that you consider the form of supplies you’ll be dealing with. Different devices are optimized for various supplies, so deciding on the correct a person could make a giant distinction. One example is, a sheet metal laser cutter is exclusively suitable for cutting by way of metallic sheets, making it ideal for fabricators and suppliers.

CNC laser cutting techniques characterize the top of modern automation in chopping technological know-how. CNC, or Pc numerical Management, signifies that these equipment are operated via Pc packages. This volume of automation permits extremely sophisticated and repetitive cuts being built with consistent precision. It’s like possessing a robot using an impeccable memory and ability set focusing on your job.

Laser chopping equipment will also be a game-changer for prototyping. In item style and advancement, speed is vital. get started Laser reducing permits designers to immediately make prototypes and take a look at them, generating adjustments as necessary. This speedy prototyping functionality can accelerate the development cycle, helping providers convey new products and solutions to sector speedier.

A different advantage of laser reducing is its minimal influence on the fabric currently being Lower. In contrast to some cutting solutions that will result in warping or other distortions, the concentrated laser beam produces clean, specific cuts with no affecting the bordering parts. This top quality is especially significant in programs where product integrity is essential.

Unknown Facts About Sheet Metal Laser Cutter

When talking about laser slicing know-how, it’s truly worth noting its environmental benefits also. Laser cutting is a relatively thoroughly clean method when compared with regular procedures, which often can crank out many dust and particles. This implies considerably less mess and probably significantly less want for additional clean-up or disposal, rendering it a far more environmentally friendly option.The ability of laser cutters to generate elaborate designs and types also opens complete info up new prospects discover more for Inventive projects. Artists and designers can experiment with intricate styles and kinds that will be difficult or unachievable to accomplish with standard methods. It’s like supplying your creativeness a tool which can flip any thought into truth.

With regard to upkeep and operational prices, laser slicing machines are commonly really efficient. They generally need fewer upkeep than conventional slicing tools, and their operational costs might be lower due to decreased will need for consumables. This could make them a value-effective selection in the long run, despite the First investment.

For firms looking to remain forward of your curve, incorporating laser reducing into their operations can offer a significant competitive edge. The pace, precision, and flexibility of laser cutting technological innovation can help companies supply superior-high quality items promptly and competently, maintaining them ahead in a fast-paced market place.

Teaching and talent development are important when working with laser slicing techniques. When these equipment are really automatic, understanding how you can set them up and operate them correctly is vital. Several firms present teaching systems in order that their team can take advantage of of the Innovative know-how.

Fascination About Cnc Laser Cutting

The way forward for laser cutting technological know-how is vibrant, with ongoing improvements promising even larger abilities. Improvements in laser chopping equipment and strategies are constantly increasing what’s doable, from chopping even thicker products to improving speed and efficiency. Keeping up Using these traits can help companies leverage the latest developments to their advantage.

For those considering laser cutting for his or her jobs, it’s important to do the job with professional gurus. Irrespective of whether you’re employing a assistance or buying your very own products, ensuring that you have the right know-how may make all the real difference. A nicely-trained operator or simply a reputable support provider will let you obtain the very best results with the laser reducing endeavors.

Laser chopping is becoming a fundamental aspect of modern producing and design and style. Its ability to offer you precision, efficiency, and flexibility makes it a worthwhile tool throughout many industries. From generating intricate styles to boosting production procedures, laser chopping technological innovation proceeds to shape how we Develop and generate.

Kelly McGillis Then & Now!

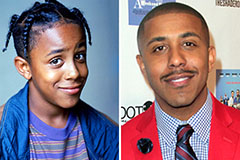

Kelly McGillis Then & Now! Marques Houston Then & Now!

Marques Houston Then & Now! Danica McKellar Then & Now!

Danica McKellar Then & Now! Sydney Simpson Then & Now!

Sydney Simpson Then & Now! Freddie Prinze Jr. Then & Now!

Freddie Prinze Jr. Then & Now!